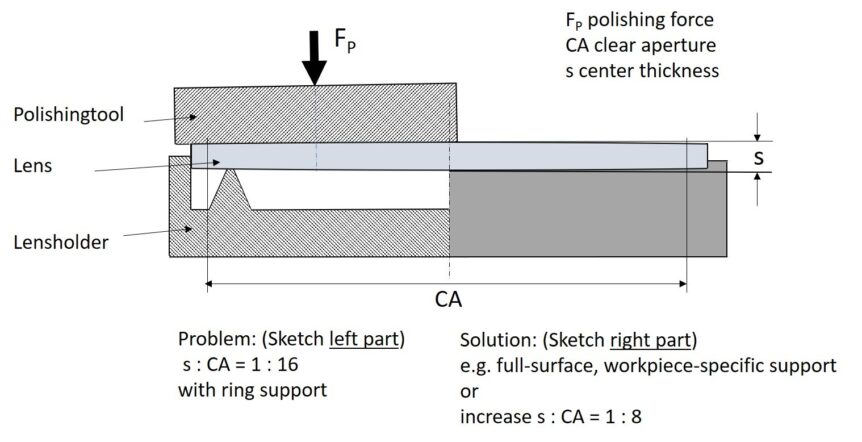

For chemical-mechanical polishing of optical surfaces, a certain contact pressure between the polishing tool and the workpiece surface is necessary. It is determined via the polishing force FP and the tool size. If this pressure is not transferred on the entire surface of the workpiece holder, undesirable deformations in the workpiece can occur, which ultimately lead to shape defects. For thin lenses with larger diameters, this is more evident and the production chain must be adjusted accordingly.

PanDao takes this into account and handles lenses depending on their ratio center thickness to clear aperture as following:

Up to a ratio of center thickness to clear aperture (CA) of 1 : 8, it is possible in practice to work without problems and with universal workpiece supports, e.g. ring support (see sketch left part), local stiff fixture out of clear aperture or soft full aperture fixture.

Beyond this, i.e. for ratios of center thickness to clear aperture of 1 : 8 down to a minimum of 1 : 30, a full-surface, workpiece-specific support is required for polishing (see sketch right part). The resulting higher tooling/mounting costs are taken into account by PanDao in the design of the production chain. In addition, PanDao displays for the computed production chain a warning if this case applies.

Ratios of center thickness to clear aperture smaller than 1 : 30 are not considered economically feasible. PanDao will display an error when entering such lens data and not compute a result.